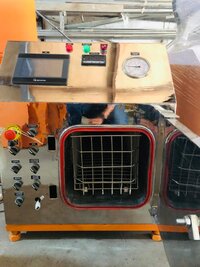

ETO Sterilizer

Product Details:

- Application Hospitals

- Dimension (L*W*H) As per customer requirement

- Operate Method Fully Automatic

- Material Stainless steel

- Capacity 55 liter, 85 liters, 110 liters

- Classification ETO STERILIZER

- Product Type Sterilization product

- Click to View more

ETO Sterilizer Price And Quantity

- 305000.00 - 800000.00 INR/Piece

- 1 Unit

ETO Sterilizer Product Specifications

- 3-10 Millimeter (mm)

- As per customer requirement

- Sterilization product

- Hospitals

- Stainless steel

- Specially designed not opened during running cycle.

- Fully Automatic

- 2 - 9 CUFT

- 55 liter, 85 liters, 110 liters

- ETO STERILIZER

ETO Sterilizer Trade Information

- 5 Unit Per Month

- 25 Days

- All India

Product Description

In the area of extensive industrial applications, the Industrial ETO Sterilizer genuinely stands out as an exceptional sterilization technology. The exacting requirements of industrial settings, notably those engaged in the production of medical devices, medications, and food preparation, have been carefully considered while creating this cutting-edge Industrial ETO Sterilizer. The use of the very successful Ethylene Oxide (ETO) sterilization procedure, which is renowned for its amazing capacity to eradicate a wide range of illnesses including bacteria, viruses, and spores, is what makes it unique. This tried-and-true technique has developed a reputation for being exceptionally effective.

Here's a brief overview of how a industrial ETO sterilizer works:

1. Loading: The items to be sterilized are loaded into the stainless steel chamber, ensuring proper placement and spacing for effective sterilization.

2. Preconditioning: The chamber is sealed, and a controlled amount of moisture is introduced to precondition the materials and enhance the sterilization process

3. Gas Injection: Ethylene oxide gas, typically mixed with other gases such as carbon dioxide or Freon, is injected into the chamber. The gas permeates the materials and kills microorganisms by interfering with their cellular processes.

4. Exposure Phase: The gas concentration and exposure time are maintained within predetermined parameters to ensure effective sterilization. This phase allows the gas to penetrate and kill any remaining microorganisms.

5. Aeration: After the exposure phase, the chamber is purged with a filtered air or inert gas, removing the residual gas and reducing the ethylene oxide concentration to safe levels.

6. Degassing: The sterilized items are transferred to a separate area where the ethylene oxide gas is removed through a degassing process. This step is crucial to ensure that the items are safe for handling and use.

Industrial ETO sterilizers are commonly used in healthcare facilities, laboratories, and other settings where heat-sensitive and moisture-sensitive equipment or materials need to be sterilized. They offer an effective solution for achieving high-level sterilization while maintaining the integrity of the items being processed.

Features of ETO Sterilizer

- A cutting-edge touchscreen control panel for the Industrial ETO Sterilizer enables simple operation.

- It has a large sterilizing chamber with enough room to fit a variety of medical and laboratory instruments.

- With safety in mind, the sterilizer is built with many levels of defenses including pressure sensors and temperature alerts.

- With customized sterilization cycles that can be adjusted to the unique requirements of various materials and devices, the Industrial ETO Sterilizer offers a high level of versatility.

- The equipment uses cutting-edge Ethylene Oxide (ETO) gas technology to sterilize even the most fragile and sensitive things thoroughly and effectively.

- The Sterilizer produces the ideal atmosphere for the efficient elimination of bacteria thanks to its exact temperature and humidity control.

ï

Added Information:

- Pay Mode Terms: T/T (Bank Transfer),Other

- Port of Dispatch: AHMADABAD FACTORY PLACE

- Delivery Time: 30-45 WORKING DAYS

-

Packaging Details: IT CAN BE PROVIDED WITH STANDARD PACKAGING AND WITH WOODEN PACKING*.

Standard Dimension:

|

Chamber Dimension (MM) |

Chamber Volume (Cu.FT/LTR) |

|||

|

W (MM) |

H (MM) |

D/L (mm) |

||

|

600 |

600 |

1200 |

16/450 |

|

|

600 |

600 |

1500 |

20/560 |

|

|

900 |

900 |

1200 |

24/680 |

|

|

900 |

900 |

1500 |

45/1270 |

|

|

900 |

900 |

1800 |

54/1530 |

|

|

1200 |

1200 |

2400 |

128/3620 |

|

FAQ:

1. How long does it take an industrial ETO sterilizer to disinfect items?

Ans: Depending on the size and complexity of the products, the time required to sterilize them using an industrial ETO sterilizer can vary, but it normally lasts a few hours to several hours.

2. Can delicate or sensitive things be sterilized with an industrial ETO sterilizer?

Ans: Yes, since an industrial ETO sterilizer delivers a mild sterilization technique that reduces possible harm, it may be utilized for sensitive or fragile products.

3. Does utilizing an industrial ETO sterilizer need any special concern for the environment?

Ans: Yes, there are environmental issues when utilizing an industrial ETO sterilizer since ethylene oxide (ETO) needs to be handled, ventilated, and disposed of properly to have as little of an impact as possible.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese